Solar Safety 102: Installation Best Practices

November 17, 2022

Solar panels are one of the most prevalent technologies for generating affordable, clean energy. In the last decade, the cost to install solar in the US has dropped by more than 60%, leading the industry to expand into new markets and deploy thousands of systems nationwide, according to the Solar Energy Industries Association. The recent passing of the Inflation Reduction Act has made renewable energy projects even more cost competitive, introducing many to solar energy's environmental and economic advantages.

The widespread adoption of new innovative technologies often coincides with rumors regarding the alleged dangers that they may pose to the general public. In the first iteration of this series on the realities of solar panel safety we reviewed what solar panels are made of, and explained how the combined raw materials safely convert sunlight into usable electricity without endangering the nearby residents and businesses. In this blog, we will discuss the standardized installation practices and regulations that make rooftop solar panels arguably safer than other commonplace appliances, such as HVAC systems, refrigerators, and microwaves.

Industry Standards That Minimize Risks

A properly engineered and installed rooftop solar array adds very little risk to a building or anyone’s safety. In the last decade, the solar industry has made many improvements in the technology used and the international standards regulating system installations. These advancements protect the equipment and the people interacting with it.

PV modules must comply with international electrical performance and safety standards. To minimize risk, inverters include ground fault, overload, over-temperature, and arc fault protection. Let’s dive deeper into two of those key ways that solar installers ensure the safety of your solar panel system: solar panel grounding and rapid shutdown.

- Grounding your panels is an effective method for protecting both yourself and your property from electrical surges. “Grounded” panels will divert excess and dangerous electrical currents away from your building and disperse them into the ground safely.

- “Rapid shutdown” is an electrical safety requirement that keeps first responders safe by ensuring that rooftop solar panel systems can quickly de-energize when necessary. If a fire (or thermal event) occurs on a site, the PV components (inverters and breakers) are programmed to shut down the system to stop the source of the fire from continuing to create an issue. The rapid shutdown rule was first introduced in the 2014 version of the National Electrical Code. It was modified further in the 2017 NEC to include module-level shutdown, which prevents the DC (direct current) wiring from remaining energized while the sun is shining.

Design elements like these have made solar panels much safer than most electrical equipment in your home. Additionally, module-level power electronics (MLPEs) monitor the modules, making it easier for problems to be identified quickly. In the case of a thermal event, a notification is automatically sent to the operations and maintenance (O&M) team, who promptly coordinates the removal and subsequent repair or replacement of the components that caused the thermal event.

Precautionary Checks And Inspections

Before connecting a solar system to the electric grid, a representative from your local government will need to inspect and approve the system, double-checking your installer’s work. They will verify that the electrical wiring was done correctly, the mounting was safely and sturdily attached, and the overall install meets standard electrical and roof setback codes.

Following this local inspection, your system will be ready for official grid interconnection, requiring a representative from your utility company to come by to do their own final evaluation of the solar panel system. As long as no glaring issues are found during this third round of due diligence, your system will be connected to the grid.

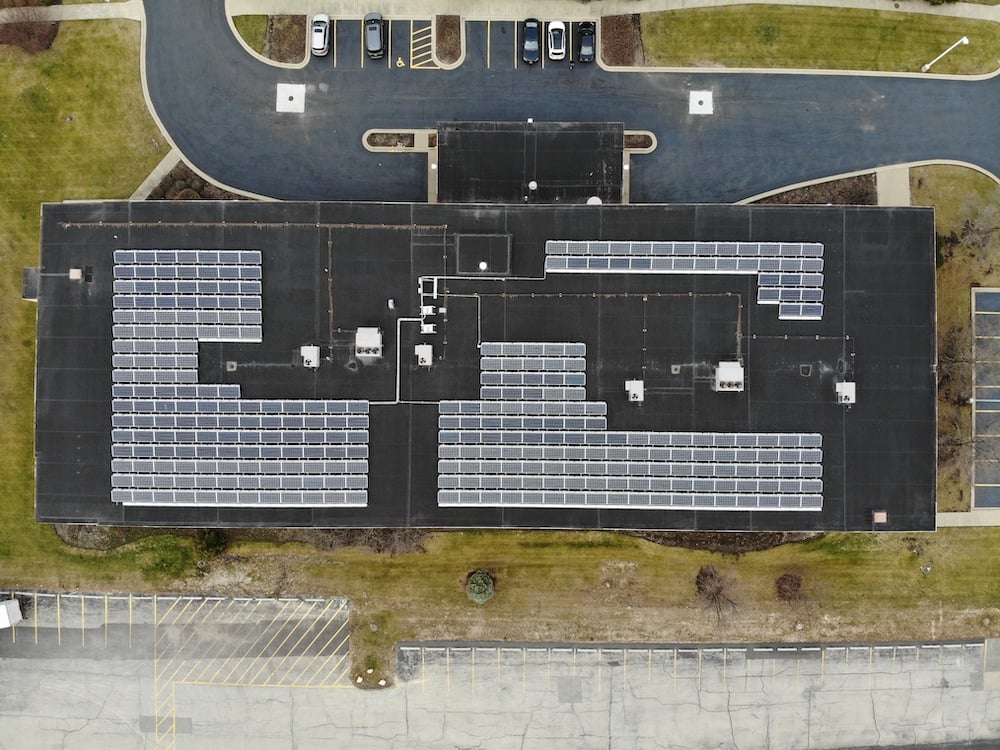

Once connected to the grid, we recommend that O&M inspectors visit at least once per year to ensure that all mechanical components continue to operate safely over the lifetime of the system. When possible, we recommend that your O&M inspectors visit twice per year, and that you schedule an annual aerial inspection to best identify and resolve any potential failure points in the array. Additionally, you will always have the option of bringing in a third party to validate these results or provide an unbiased extra level of scrutiny.

Thanks to all of these precautionary steps, solar panels are overwhelmingly safe.

The data truly speaks for itself. A 2017 report by NREL found that only 5 out of 10,000 solar panels developed faults - that is just 0.05%. And that figure includes faults of any kind – the number of panels that malfunctioned in a dangerous way is a small percentage of that already tiny percentage. Solar equipment has very robust warranty coverage, meaning that any equipment that does have manufacturer defects will be replaced with new equipment.

- Modules typically have a 25-year warranty

- Inverters have a 10-year warranty

- Racking has a 25-year warranty

- The system as a whole has a 2-3 year workmanship warranty

Pick The Best Installers For The Best Results

It is always best to ensure that you are using an installer with a good track-record. Ask your installer to share past projects, showcasing that they have worked on similar projects to the one you are planning. Ask to see your installer’s certifications from industry boards like the North American Board of Certified Energy Practitioners (NABCEP) and Solar Energy International (SEI). Lastly, your installer should include a workmanship warranty to ensure that any missed errors in the inspection process will be corrected at no added cost to you or the system owner.

Working with a trusted solar provider, such as Pivot Energy, will ensure that you safely navigate all possible hurdles that may arise in constructing a new project. Reach out to learn more about our installation process, and to discuss whether or not building a new project is right for you.